Objective: Design a robot capable of lifting and placing items up to 1 kg and 540 cm² onto a 36” high shelf

Design Constraints: Robot can be no larger than 16” × 12” × 12”, weigh no more than 12 lbs, and can use a maximum of 4 servo motors and 4 LDO torque motors

Skills Learned: Solidworks CAD designing, prototyping, and manual machining

Challenge

Finding a lift mechanism that must reach 36" in height, extend up to 18", allow for the ease of collecting and deploying various objects, and meeting all design constraints, particularly size constraints, was the main challenge.

This led me to implement my own version of a ' coaxial virtual four bar'.

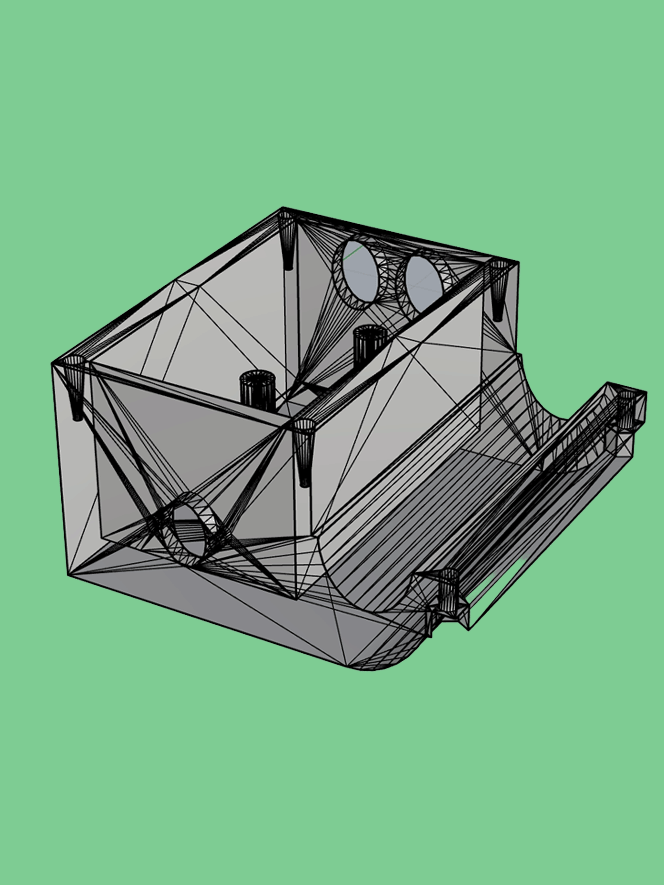

First CAD Model

With this first iteration I took great focus on:

• Making sure the overall height of my robot is less than 16"

• Having some sort of arm mechanism which can extend more than 18" from the front of the robot

• Have the ability to control the arm mechanism and the bucket mechanism separately

First Iteration

Pros

• Met all size constraints

• Could reach top shelf without tipping over

• Slacked chains leading to unsuccessful bucket or arm actuation. Due to resource constraints, I was unable to use the mesh gears my design was originally built for and had to switch to using chains and sprockets while lacking proper chain tensioning mechanisms

• The back of the robot was too heavy, requiring steel weights in the front of the robot for torque balance on the wheels of the robot

Second Iteration

Pros

• Due to a new redesign of the housing of all the servos and gear shafts, all chains were properly tightened, allowing for proper actuation

• Gear Shafts were not properly leveled, leading to a dynamic imbalance, increased power transmission inefficiency, and increased shear stress eventually lead the shafts to fracture

• Could not carry more than 250g, much less than the 1kg heart

• Could not pick up objects independently, needed to use a wall as a support

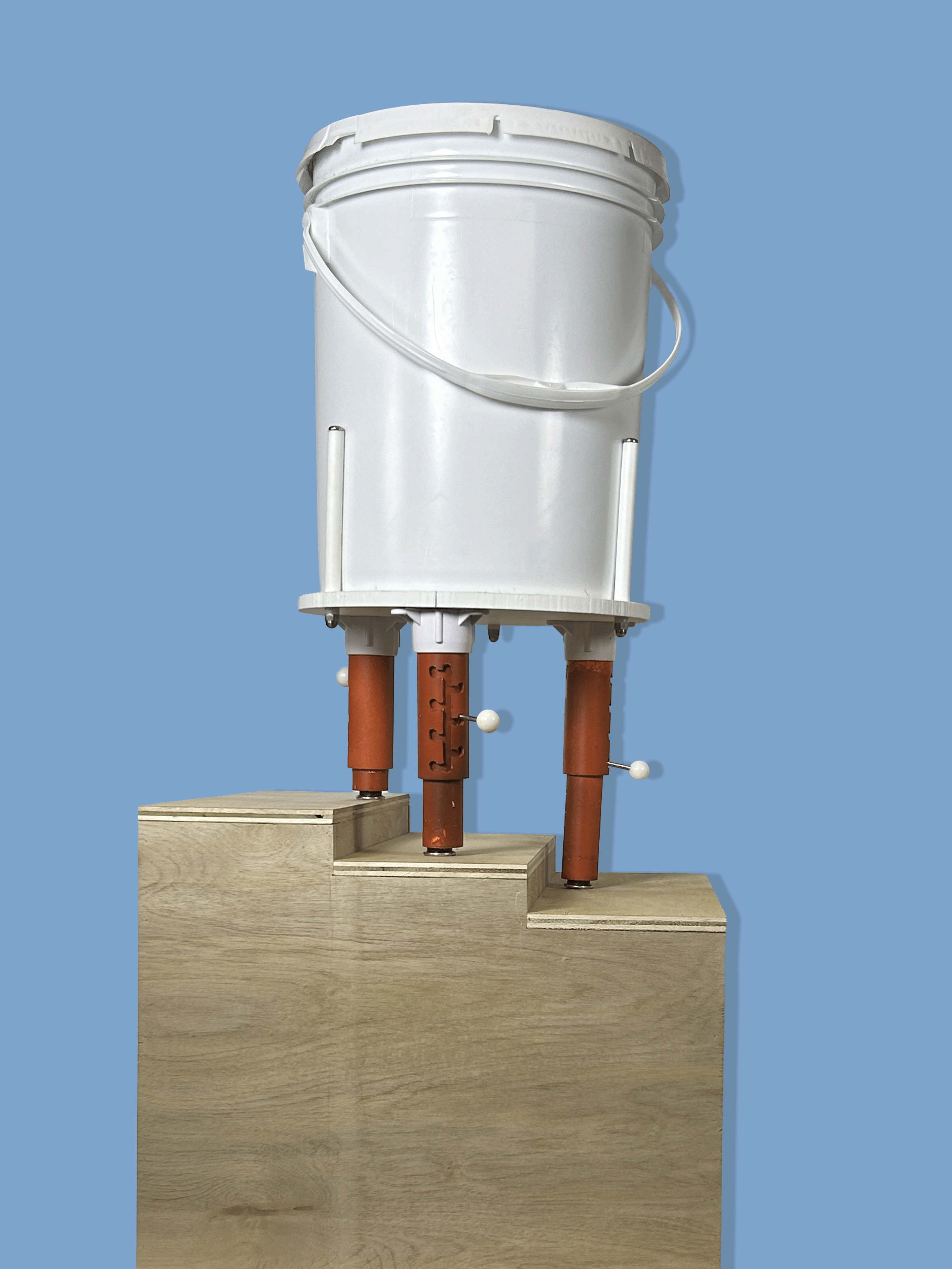

Final Product

• Met all design constraints

• Added a 2:1 gear ratio to increase torque output, meeting the payload of all artifacts except the 1kg heart.

• Redesigned gear's placement to ensure torque balance around the wheels

• Added LDO motor powered 'claws' for ease of artifact collection

• Ensured the bucket and arms had separate degrees of freedom, allowing for easy artifact collection and deployment